Advanced Forging and Milling Solutions

Home > Product & Solutions > Steam Turbine Blades

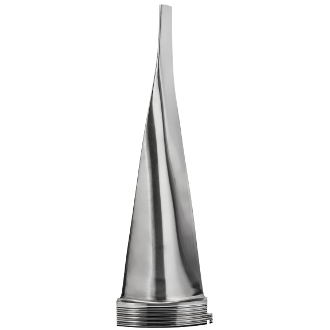

Steam Turbine Blades

Our company is specialized in the forging and machining of Steam Turbine Blades with overall length up to 1.500mm (59inch) and initial weight amounting up to 180kg (400lb).

Our expertise and equipment allow us to quickly manufacture big Low Pressure Turbine Blades and Vanes with excellent quality and competitive cost.

The fully integrated production cycle and supply chain enable C*Blade to act as One-Stop Shop for the supply of Ready To Fit Blades for Steam Turbine.

Steam Turbine Blades |

|||

Turbine Output |

20 MW - 1.800 MW | ||

Turbine Section |

High Pressure | Intermediate Pressure | Low Pressure |

Blade Types |

Blades / Vanes | ||

Overall Length / Chord |

100mm (4") - 1.500mm (59") / Up to 500mm (20") | ||

Maximum Input Weight |

180kg (400lb) | ||

Production Process |

Forging + Machining / Milling from bar | ||

Materials |

Stainless Steel / Titanium Alloy (click here for details) | ||

Scope of supply

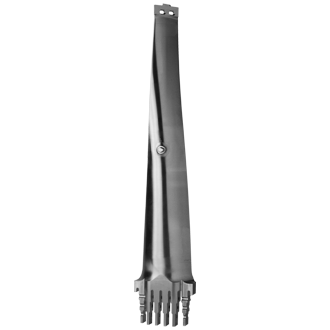

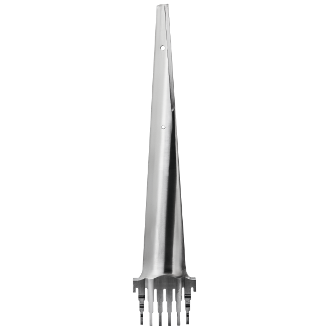

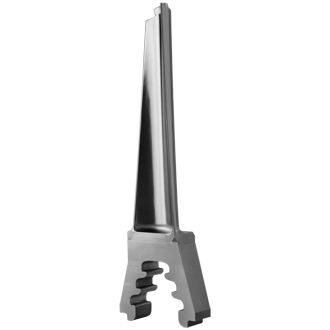

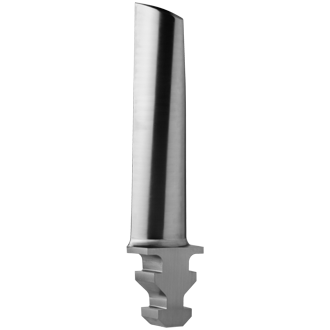

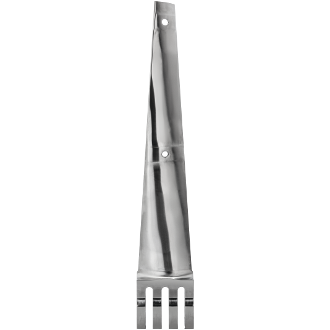

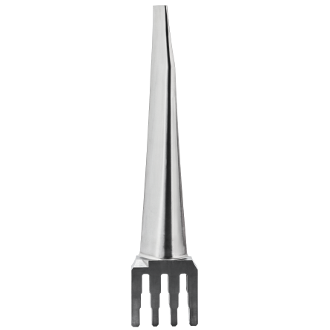

Envelope Forged Blades

Forged with 5mm Envelope on all surfaces and with centering holes

Airfoil Machined Blades

Forged with 5mm Envelope on all surfaces and with centering holes, Machined and finished on the airfoil and on the root ramp, not on the root and the shroud (if applicable)

Complete Machined Blades

Forged with 5mm Envelope on all surfaces and with centering holes, Machined and finished on the airfoil, the root and the shroud (if applicable)

Ready To Fit Blades

Forged with 5mm Envelope on all surfaces and with centering holes, Machined and finished on the airfoil, the root and the shroud (if applicable) and where required, shot peening (ext.), hardening (ext.), stellite brazing/cladding (ext.), frequency test and weight moment balancing

Reference list

- ALSTOM, ABB, GEC-Alsthom, Alsthom, GEC, BBC technology

- ANSALDO technology

- FRANCO TOSI technology

- GE technology

- HITACHI technology

- MAN technology

- PARSONS technology

- SIEMENS, KWU, AEG technology

- SKODA technology

- TURBOATOM technology

- URAL TURBINE WORKS technology

- WESTINGHOUSE technology

- ZAMECH technology

C*Blade S.p.A. Forging & Manufacturing

Registered Office Via Genova 1, 33085 Maniago (PN) ITALY

Register of Companies of Pordenone 73282

Fiscal Code and VAT number IT 01391770938

Company under control of Ethica Global Investments S.p.A.

Terms of Use | Privacy Policy

Copyright © 2007- C*Blade S.p.A.

Phone: +39 0427 735411 / Fax: +39 0427 700141