Advanced Forging and Milling Solutions

Home > Process > Why Forging is better

Why Forging is better

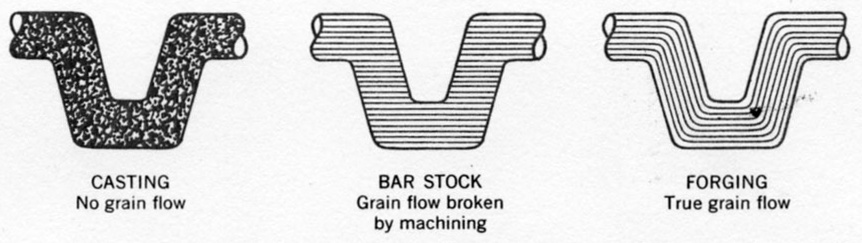

Forging is a superior to machining bar stock since the metal's natural grain flow is made to conform to the shape of the product. For this reason, forgings are superior in tensile and shear loads.

Our forgings are normally made from special bar quality steel. As steel bars are usually rolled, the grain structure within the steel is forced to flow along the centerline of the bar. When a forging is produced from the bar, this inherent grain flow bends to follow the contour of the forged shape, thus producing a superior part.

Any machined part, whether produced from bars or plate, will by definition cut through part of the grain flow. This renders the material more liable to fatigue and more sensitive to stress corrosion cracking.

The structural reliability of forgings allows designers to trust the material to adhere to the safety factors of the design. It also can provide more uniform response to heat treatment and machining operations.

- Forgings offer broader size range of desired material grades.

Sizes and shapes of products made from steel bar and plate are limited to the dimensions in which these materials are supplied. Often, forging may be the only metalworking process available with certain grades in desired sizes. Forgings can be economically produced in a wide range of sizes. - Forgings have grain oriented to shape for greater strength.

Machined bar and plate may be more susceptible to fatigue and stress corrosion because machining cuts material grain pattern. In most cases, forging yields a grain structure oriented to the part shape, resulting in optimum strength, ductility and resistance to impact and fatigue. - Forgings make better, more economical use of materials.

Cutting of bars and plates is a wasteful process that consumes more material than needed.

Even more is lost in subsequent machining. - Forgings yield lower scrap; greater, more cost-effective production.

Forgings make better use of material and generate little scrap.

In high-volume production runs, forgings have the decisive cost advantage.

C*Blade S.p.A. Forging & Manufacturing

Registered Office Via Genova 1, 33085 Maniago (PN) ITALY

Register of Companies of Pordenone 73282

Fiscal Code and VAT number IT 01391770938

Company under control of Ethica Global Investments S.p.A.

Terms of Use | Privacy Policy

Copyright © 2007- C*Blade S.p.A.

Phone: +39 0427 735411 / Fax: +39 0427 700141