Advanced Forging and Milling Solutions

Home > Process > Technology

Technology

Our know how in Forging and Milling, cumulated during over 60 years of presence in the Power Generation and Oil & Gas markets allows us to tackle any challenge.

Fully Integrated

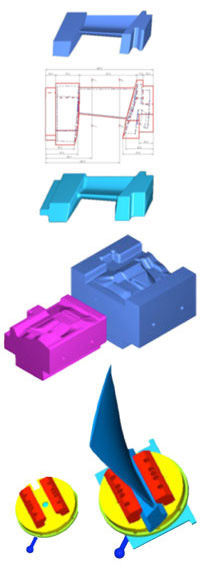

Design, Forging and Milling Process

From the drawing to the Ready To Fit component, Turbine Blades or Aerospace parts, each step is carried out inside our company thanks to the knowledge of our technicians and a high qualified process.

We are able to design the die and produce any kind of component starting from the 3D model, drawings or through reverse engineering of samples. In order to do so, we also use a FEM system for the simulation of hot plastic deformation of materials in closed die Forging. We are able to provide simulation of material flow and precise prediction of all kinds of flow induced defects. The defects and grain-flow as well as temperature, strain and fracture factor can be tracked in order to optimize the Forging process.

We also produce by ourselves the CAM programs required for the milling of the parts in our CNC machines and design any fixing and checking tool required for the manufacturing, including control programs used in our CMMs.

Quality Controls

Highly qualified technicians are able to perform a wide range of controls in compliance with the most rigorous international standards.

The mechanical properties are investigated through tensile tests, Charpy impact tests and Brinell hardness tests. Complete metallographic examinations are performed in order to determine grain size, non-metallic inclusions content and delta ferrite content. Vickers micro-hardness tests are used for surface decarburation inspection. The final product can be subjected to non-destructive tests such as magnetic particle, ultrasonic and dye penetrant examinations.

C*Blade is able to deliver Ready To Fit Turbine Blades on which are performed frequency test, weight moment measurement and calculation of the assembly sequence. The turbine blades on which additional operations are performed, such as hardening, stellite brazing or cladding, shot peening or coating, are certified according the customer requirements.

C*Blade S.p.A. Forging & Manufacturing

Registered Office Via Genova 1, 33085 Maniago (PN) ITALY

Register of Companies of Pordenone 73282

Fiscal Code and VAT number IT 01391770938

Company under control of Ethica Global Investments S.p.A.

Terms of Use | Privacy Policy

Copyright © 2007- C*Blade S.p.A.

Phone: +39 0427 735411 / Fax: +39 0427 700141